Formulation Troubleshooting Support Services

Natoli organization is a reputed leader with more than a half century experience in the tablet manufacturing technology.

We understand that these late-stage development problems require ‘Quick-Fix’ without regulatory agencies involvement. We are here to provide most possible pragmatic economic solutions for these tableting issues with very minimum or no regulatory requirements.

Natoli Understands Tablets Better!

Tablet Sticking, Tablet Picking, Tablet Capping & Lamination

Various challenges like tablet sticking, picking, and lamination during the late development stage or actual tablet manufacturing requires mechanistic understanding. Such understanding is necessary to design effective strategies to solve these challenges.

Our designed ‘Natoli in-house’ testing approach coupled with FT4 rheometer along with dynamic compaction profiling will help you to decode the influence of material properties and tooling composition on tablet sticking, picking, and lamination.

Tablet Sticking, Tablet Picking, Tablet Capping & Lamination

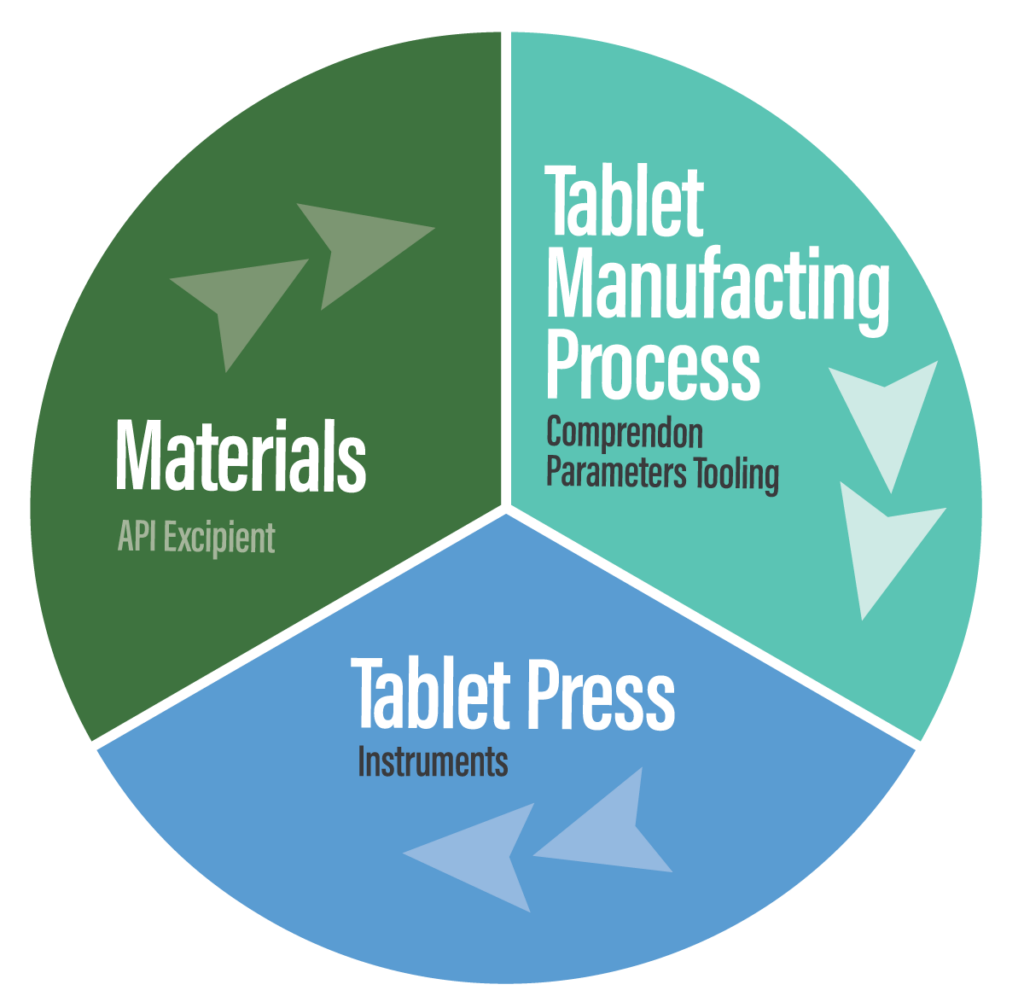

A successful compact of your formulation is a right marriage of material response to tablet manufacturing condition. An early entry of compaction simulation in the formulation development can predict the manufacturability of the tablet product.

Simulating high speed manufacturing conditions with Presster will allow to evaluate your formulation response to real production scenario.

Natoli compaction simulation service could possibly eliminate scale-up surprises and smooth transition from lab to scale-up to actual manufacturing.

Tablet Tool Coating Selection

Depending on the out-come of mechanistic understanding generated with ‘Natoli in-house’ testing approach coupled with FT4 rheometer along with dynamic compaction profiling, we will guide in proper selection and designing of tooling or coating for your challenging formulations posing sticking problem.