Powder Flow Properties & Characterization

Basic Powder Flow Characterization [USP <1174>]:

A powder flow analysis is an indicator of how well formulation will release from the hopper during the tableting. It is important to know that the developed formulation is showing ‘Mass Flow’ or ‘Funnel flow’ or ‘Rat Holing’.

Powder blend shows ‘Mass Flow’ when entire solid bed is in motion during the discharge of material from the outlet. This is ‘First-in-First-Out’ process. Hoppers offering ‘Mass Flow’ have steep and/or low-friction walls. This flow offers ‘No-Arching’, ‘Less Segregation’ and ‘Stable Powder Flow’.

When hopper is not sufficiently steep and smooth enough to ensure sliding along its wall, the powder blend exhibit ‘Funnel Flow’. Such hoppers are sensitive to arching and ratholing. In this case, powder discharge from hopper is not predictable.

Major Testing:

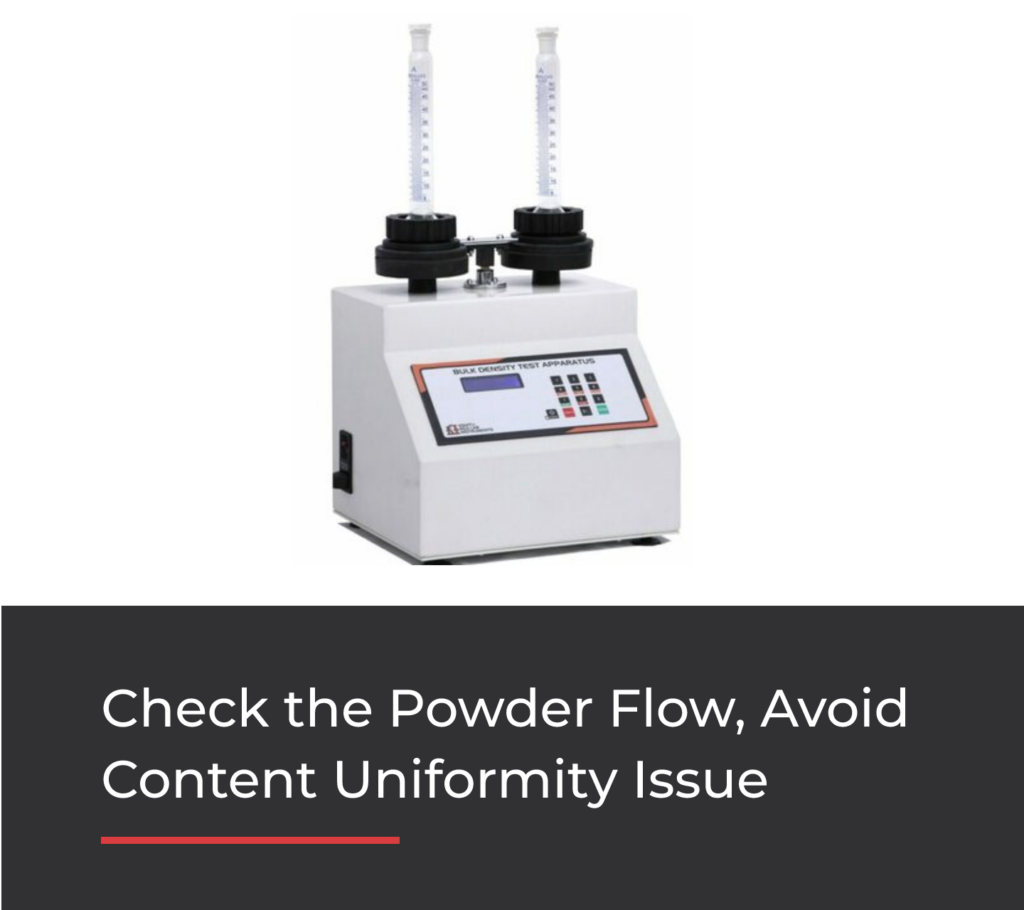

- Bulk Density Measurement [ USP<616>]

- Tapped Density Measurement [ USP<616>]

- Compressibility Index [ USP<616>]

- Hausner Ratio [ USP<616>]

- Angle of Repose

Advanced Powder Flow Characterization:

When your formulation is posing challenges for discharging powder from the hopper and traditional basic powder flow characterization USP<1174> is not helping you to understand the complex flow behavior of the powder, we are here with advanced powder flow testing!

We will help you to understand complex powder flow behavior, which will not be assessed with USP<1174> and <616> testing. We offer advanced powder flow testing using FT4 Rheometer. Analysis will be performed with application of Mohr’s Circle principles. We can also model and develop a quality control protocol’ for the micrometrics properties of your incoming raw materials which are possibly impacting the powder flow.