Add-on Tablet Quality Control Testing

We offer several add-ons testing in addition to detailed compression profiling of your

- API and lead formulations

- Active pharmaceutical ingredient and lead formulations

These tests are vital of your early development program and routine quality control regimen.

Know Your Tablet Strength:

Tablet strength is an important guiding criterion for product development and as a quality control specification. We offer tablet strength measurements with Tablet Friability and Breaking Force testing as per USP recommendations.

Tablet friability tests tablet’s durability during the transportation and handling. Friable tablets have tendency to chip, crumble, or break during the packing, handling, transportation. A broken tablet means incorrect dosing to the Patient. We provide Tablet Friability testing as per USP chapter < 1216> recommendations.

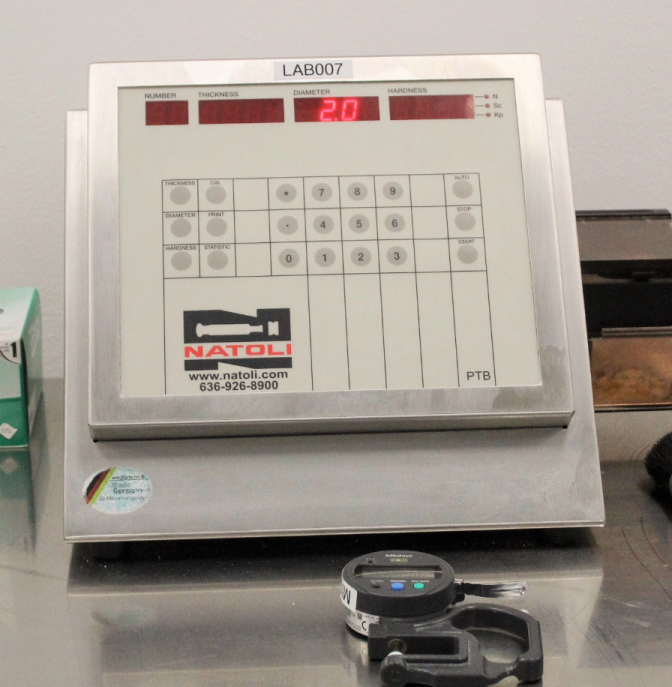

Tablet breaking force also referred as tablet hardness measures mechanical integrity of tablet. We have reliable method to measure mechanical integrity of tablets regardless of its shape from oval, convex oblong and even for special shaped tablets. This is routine test in tablet formulation development and manufacturing. We provide Tablet Breaking Force as per USP chapter < 1217> recommendations. We also use Tablet Breaking Force to compute Tablet Tensile Strength to normalize data for USP<1062>. one minute.

“Does Your Tablet Disintegrate within 5 minutes?”

Know How Quickly Your Tablet Breaks into Small Granules:

Tablet disintegration test determines disintegration ability of tablet and capsules within a specific time after placing in a liquid medium. This test determines how quickly tablet breaks into a smaller particle or granules to release active drug for its absorption into body.

Uncoated tablet should not take more than 5 minutes for disintegration into smaller particles. A best disintegration time for a fast-disintegrating tablets or ‘melt-in-mouth’ or ‘oro-dispersible tablet’ should not more than 1 minute.

We provide Tablet disintegration test as per USP chapter < 701> recommendations.

Major Testing:

- Tablet friability USP<1216>

- Tablet breaking force <1217>

- Tablet disintegration testing USP <701>

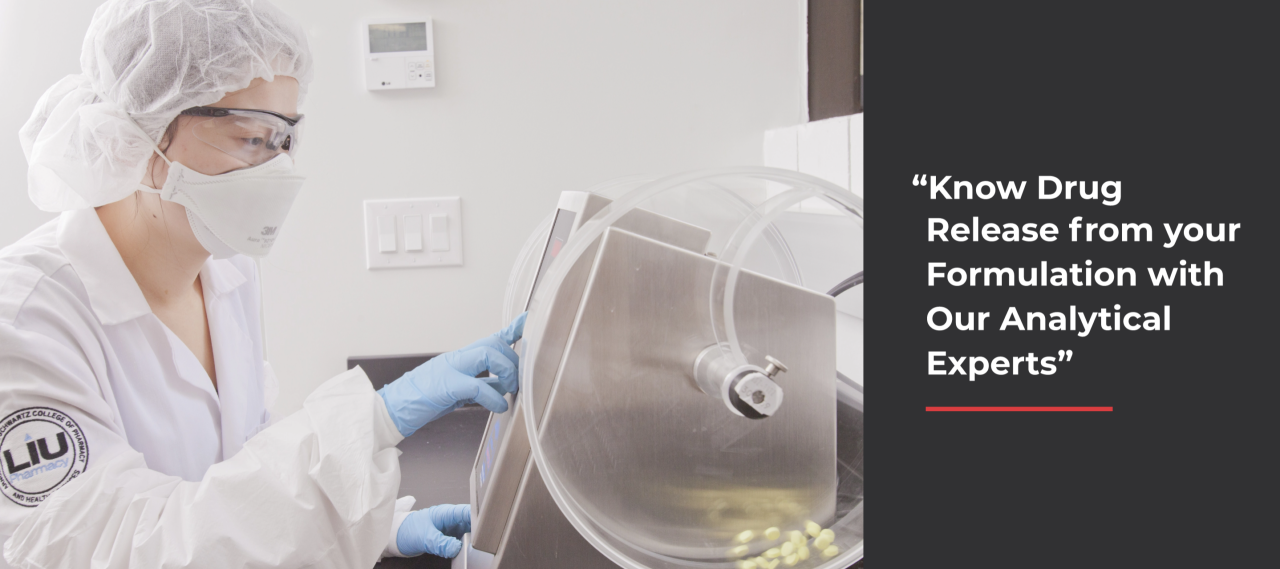

Know Your Drug Release from Developed Tablet:

Drug Dissolution test is a USP recommended method to measure the release rate of a drug from the given dosage form. The measured drug release rate is ‘in-vitro’ method used to evaluate the performance of the drug. This is because the extent of drug absorption depends on its dissolution from the formulation. The USP chapter <711> has recommended this test to ensure batch-to-batch consistency of developed dosage form.

Our analytical team have the tools and expertise to develop dissolution and drug release testing protocols for any solid dosage form. We deliver sound and scientifically backed analytical data to support your formulation development program and regulatory filing. Our team has skills in UV/Vis and HPLC analysis to handle your complex API drug products. We will perform dissolution testing under specific conditions as per the specification given in the United States Pharmacopeias or other pharmacopeial standards as per your market requirements.

We can establish dissolution testing protocol for your new active pharmaceutical ingredient. We can generate rational and data-driven methodology to set dissolution specifications to avoid uncertainties about the product quality.

We can develop dissolution testing protocols for:

- water-soluble and sparingly-water soluble active pharmaceutical ingredients.

- immediate release formulations as well as for modified release formulations.

- uncoated tablets, enteric-coated tablets, and chewable tablets.

Instrumentation:

- Woods Dissolution Test Apparatus

- USP Apparatus 1 – Basket (37 oC ± 0.5 oC)

- USP Apparatus 2 – Paddle (37 oC ± 0.5 oC)

- Agilent 1100 HPLC

Major Dissolution Services Offered:

- Intrinsic Dissolution Testing

- Developing Discriminatory Dissolution Media

- Single Vs Multi-Medium Dissolution Testing

- Developing Tablet Dissolution Testing USP<711>

Deliverables:

- Data analysis

- Full project report

Uniformity of Dosage Units:

The ‘Uniformity of Dosage Units’ ensures the uniform amount of the drug substance among the dosage units. The USP chapter <905> has recommended two important tests to ensure uniformity of dosage units. These tests are as follows:

- Weight variation

- Content uniformity

Our analytical team have the tools and expertise to perform these tests for a prescribed solid dosage form. We perform ‘Uniformity of Dosage Units’ test as per the pharmacopeial specifications [USP Chapter <905>].

Our team can provide highly accurate and reliable analytical data to support your formulation development program and regulatory filing. This will also help to perform early risk assessment of the finished product.

Preliminary and Accelerated Stability Studies:

Stability data is a critical component of the drug approval process. Stability testing determines the possible reactivity of drug product including its packaging over time under the influence of temperature, humidity, and light. This process determines the possible physical, chemical, and microbiological changes responsible for affecting the efficiency and integrity of the final product. Thus, these studies ensure the safety and effectiveness of the product regardless of its supply in any part of the world. Stability studies also establish pharmaceutical product shelf-life and recommend storage conditions of the finished pharmaceutical product.

Shelf-life of the pharmaceutical products is established with the real-time and accelerated stability studies data. A product is stored at recommended storage conditions and monitored until it fails for specification during the real-time testing. The accelerated stability study is performed by exposing pharmaceutical products at elevated stress conditions of temperature and/or humidity. This data is used to predict the product degradation at recommended storage conditions.

Natoli Scientific has two dedicated chambers walk-in chambers with 25 oC/ 65 % RH and 40 oC/75 % % RH chambers for your short or long-term stability studies requirements.

- Analytical balances

- Two dedicated Walk-In Stability chambers for maintaining stability conditions as per ICH guidelines

(25 oC: 65 % RH; 40 oC 75 % % RH) - Agilent 1100 HPLC Major

- Weight variation

- Content uniformity

- Preliminary stability studies or forced degradation studies

- Long-term (Real-time) stability studies

- Accelerated stability studies

- Ambient storage conditions

- Data analysis

- Full project report